Products

Our Products

We are a leading supplier of feeding systems in India, providing high-quality solutions for material handling and automation systems across a range of industries.

We specialize in the design, manufacture, and supply of high-quality vibratory feeders for a wide range of industries. Our vibratory feeders are engineered to meet the specific needs of your application, providing reliable and efficient material handling solutions.

Our product range includes a variety of vibratory feeders, each tailored to suit different applications and materials. We also offer customization options for our vibratory feeders, including adjustable feed rates, multiple tray sizes, and different vibration frequencies. This allows us to tailor our products to meet the specific needs of your application.

Our vibratory feeders are built to last, using high-quality materials and components that ensure reliable operation and minimal maintenance. We use state-of-the-art manufacturing techniques to ensure consistent quality and performance across our product range.

At our company, we are committed to providing our customers with the highest level of service and support. Our experienced team of engineers and technicians is available to answer any questions you may have and provide expert advice on selecting and using vibratory feeders. We also offer support and maintenance services to ensure that your equipment is always operating at peak performance.

Contact us today to learn more about our vibratory feeders and how they can improve your material handling processes

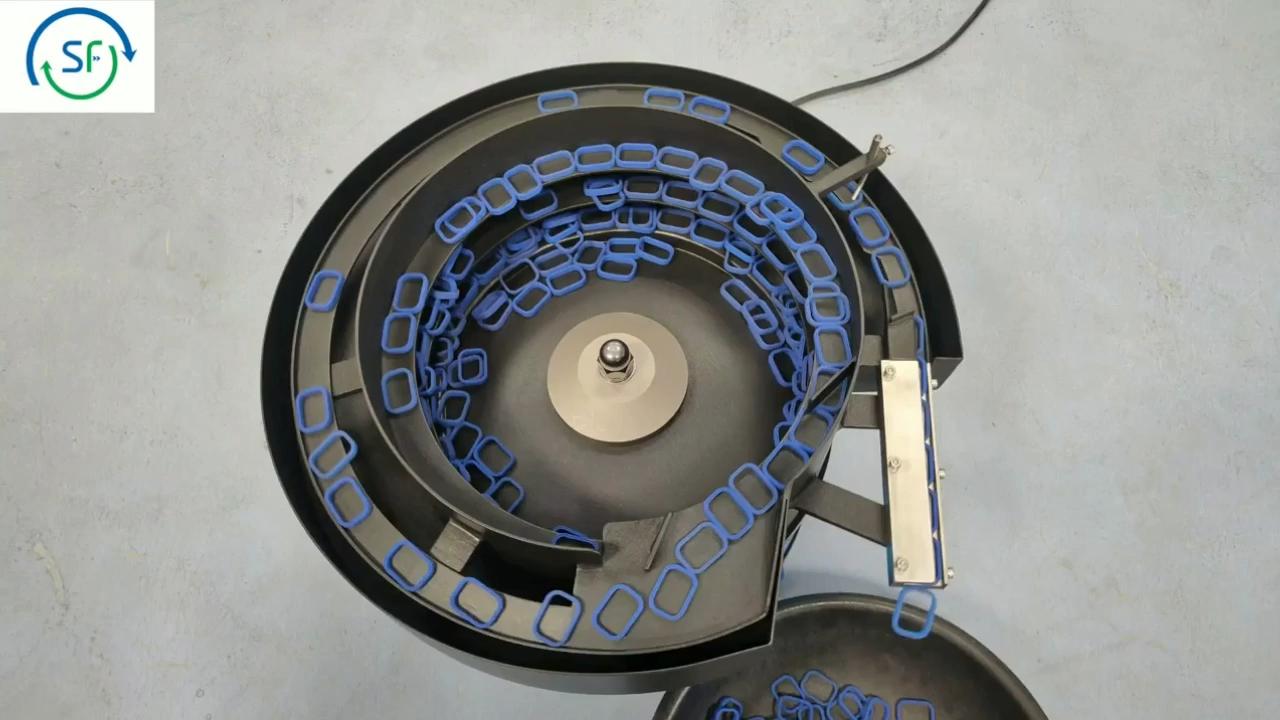

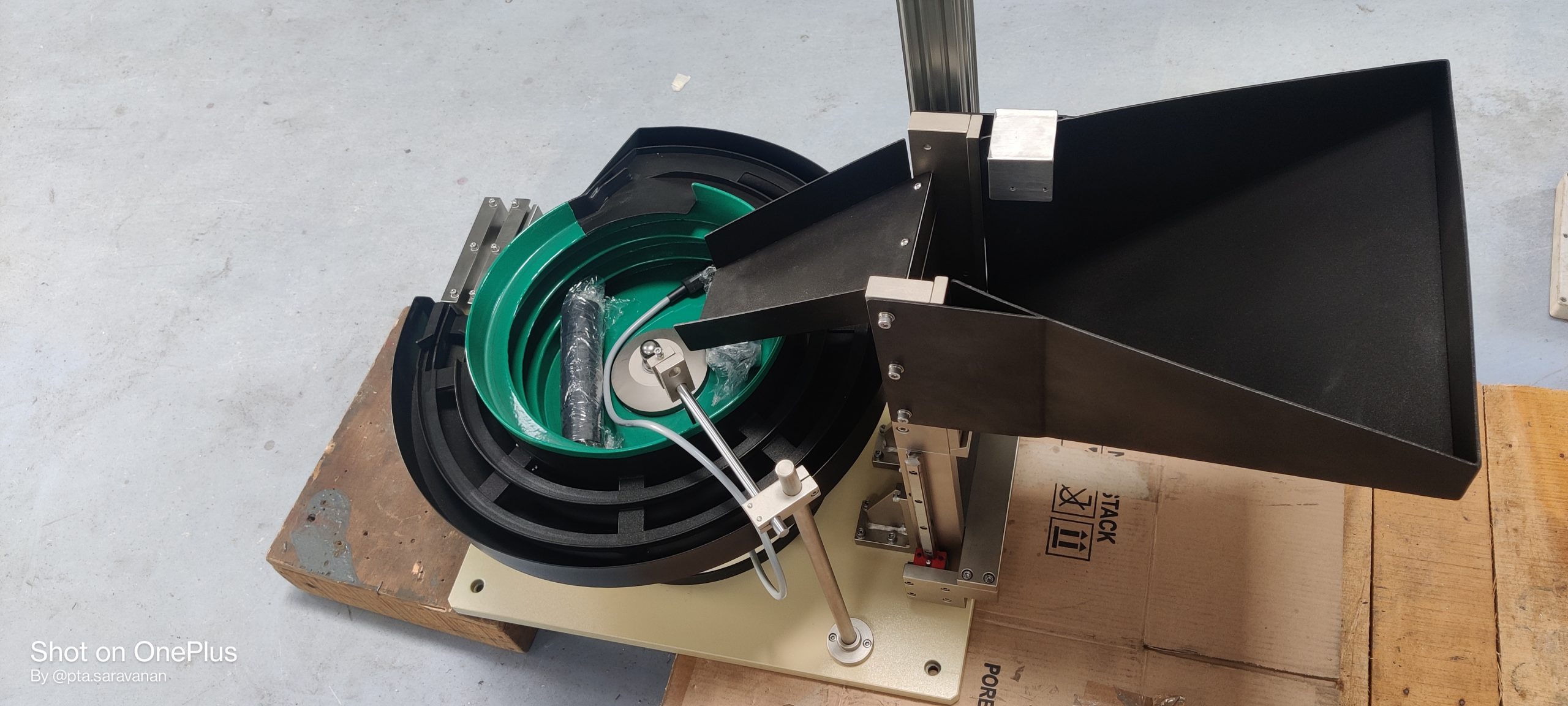

Bowl feeders

Bowl feeders, also known as vibratory bowl feeders, are a type of material handling equipment used to sort, orient and feed small and light-weight components automatically. They are widely used in a variety of industries, including automotive, electronics, medical, packaging, and more

In bowl feeders there are three types

- Cylindrical

- Conical

- Step

Choosing the right type of bowl feeder is crucial for ensuring optimal performance in material handling applications. Factors such as component orientation and desired output feed rate are key considerations when selecting a bowl feeder. Additionally, providing clockwise and counter-clockwise direction bowl feeders can offer greater flexibility and customization to customers with specific requirements.

By working closely with our customers to understand their requirements and goals, we can provide tailored solutions that can help improve efficiency, reduce costs, and increase overall productivity.

Linear feeders

Linear feeders basically acts as parts discharge from a vibratory bowl feeder. They are ideal for handling longer parts and components that cannot be easily sorted or oriented by bowl feeders. It is important to maintain feed rate as parts convey horizontally to their next processing point. We offer linear feeders in different ranges depending upon customer’s requirement.

Linear feeders are commonly used in industries such as automotive, electronics, and packaging, where precision and speed are essential for efficient production. They can be customized to handle a wide range of part sizes and shapes, and can be integrated into automated production lines for increased efficiency and productivity.

Our linear feeders are built to last, using only the highest quality materials and components to ensure reliable operation and minimal maintenance.

Hopper feeders

Hopper feeders provide the most efficient and economical method of conveying bulk materials such as biomass, with the ease of controlling feed rate. Feeders satisfy a range of applications in a cost-effective way. For each application a feeder is sized and equipped with various tooling and options to suit.

Choosing the right type of Hopper feeder is crucial for ensuring optimal performance in material handling applications. Factors such as component orientation and desired output feed rate are key considerations when selecting a bowl feeder.

By working closely with our customers to understand their requirements and goals, we can provide tailored solutions that can help improve efficiency, reduce costs, and increase overall productivity.

Ball feeders

A ball feeder is a critical component of an automation industry that enables the automated feeding of balls or other small objects into a production line. The feeder typically consists of a hopper, a vibrating mechanism, a feeder channel, sensors, and a control system. The hopper serves as the primary storage container for the balls, while the vibrating mechanism agitates the balls inside the hopper to move them towards the feeder’s outlet. The feeder channel is designed to guide the balls from the hopper to the production line while preventing them from getting stuck. Sensors are used to monitor the number of balls in the hopper and the feeder channel, while the control system adjusts the speed and frequency of the vibrating mechanism to ensure a consistent flow of balls to the production line. The ball feeder plays a crucial role in the automation industry, improving efficiency, reducing labor costs, and ensuring a high level of precision and accuracy in production processes.

Controllers with specification

To ensure precise and reliable operation of a vibratory feeder, it is essential to use an appropriate controller that meets the specific requirements of the application.

Frequency Controller

Frequency controllers for bowl feeders are essential components in ensuring optimal performance and precision in feeding operations. A bowl feeder uses vibrations to move and orient parts, and the frequency controller allows for the precise control of these vibrations.

Accelerometer Controller

The inclusion of an accelerometer controller in a bowl feeder is vital in achieving precise measurement and control of acceleration or vibration. Since bowl feeders utilize vibrations to move and arrange parts, an accelerometer controller plays a crucial role in controlling these vibrations with accuracy. However, it is much constlier comparing to frequency controller.

Voltage Controller

Voltage controllers are an essential component of linear feeders, which use electromagnetic vibrations to move and orient parts in a linear direction. Voltage controllers allow for precise control of the amplitude and frequency of the electromagnetic vibrations, ensuring that parts are handled gently and efficiently.

Bowl feeder spares

To ensure that bowl feeders operate efficiently and have a long lifespan, it is important to regularly maintain and replace worn or damaged parts. At our company, we offer a range of spares specifically designed for bowl feeders, including EMF coils, rubber mounts, epoxy sheets, and more. Our high-quality spares ensure that your bowl feeder functions optimally and reliably.

Linear feeder spares

In order to maintain optimal performance and durability, it is necessary to perform regular maintenance and replace worn or damaged parts in linear feeders. To facilitate this, we offer a range of spares specifically designed for linear feeders, including EMF coils, rubber mounts, epoxy sheets, and more.